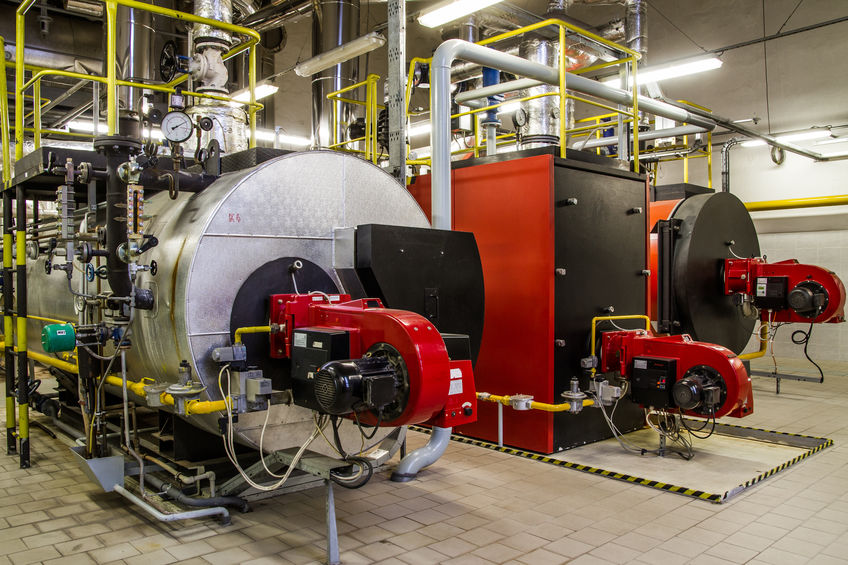

Commercial boilers are pressurized systems that burn combustible fuel or use electricity to heat water that is used to provide heating in your building or for process. Some types of boilers use the hot water itself, while others heat and convert the water to steam.

Depending on your company’s product and processes, commercial boilers can be used for heating but also for production and manufacturing. There are four main types of boilers:

- Firetube Boilers are used in facilities that have hot water applications, high-pressure steam applications, or low-pressure steam applications. Firetube boilers can be purchased in either a wetback or dryback design.

- Watertube Boilers produce hot water or steam for industrial or commercial applications, often used for comfort heating applications. Industrial watertube boilers are mainly steam boilers producing extra heat with the use of superheaters, as they are used for a wide array of applications requiring large amounts of steam and higher pressures.

- Condensing Boilers are water heaters that are fueled by gas or oil, with a high level of thermal efficiency up to 98%.

- Electric Boilers have no exhaust stack, no fuel handling equipment and no combustible fuels, because they are heated by electricity exclusively, thus they are known for being quiet, compact, less complex systems that are easier to install.

Why Preventative Maintenance is Essential

To ensure energy efficiency of your commercial boiler, as well as prevent interruption of service, it’s imperative to regularly conduct preventative maintenance checks. Because regular audits of your system are imperative to your business, this post will answer the following questions:

- What are the benefits of regular Commercial Boiler PMs?

- How often do I have to get my boiler inspected?

- Who are licensed and qualified to conduct such inspections?

- What is involved in a Commercial Boiler Preventative Maintenance (PM)?

The Benefits of Commercial & Industrial Boilers Preventative Maintenance (PM)

I. SAFETY: Since boilers are volatile systems using very hot water or steam under varying degrees of high pressure, as well as the use of gas and oil in some instances, boilers can explode causing serious injury, death and extensive property damage. To ensure safety of your employees, as well as a healthy working environment, regular maintenance of your systems is necessary to ensure the boiler is clean and working properly. Also during these regular PMs, all built-in safety systems are checked and tested for functionality .

I. SAFETY: Since boilers are volatile systems using very hot water or steam under varying degrees of high pressure, as well as the use of gas and oil in some instances, boilers can explode causing serious injury, death and extensive property damage. To ensure safety of your employees, as well as a healthy working environment, regular maintenance of your systems is necessary to ensure the boiler is clean and working properly. Also during these regular PMs, all built-in safety systems are checked and tested for functionality .

II. COMPLIANCE: The National Boiler Codes specify that all commercial and industrial boilers must be checked by a licensed boiler contractor at least once a year for High pressure steam boilers and low pressure steam and hot water boilers every 2 years. That’s a good start, but with high efficiencies of boilers such as condensing, full-modulating system (burners), it is recommended by boiler manufacturers that you have preventative maintenance checks, again by a licensed boiler contractor, at least twice per year. Keeping up with these PM’s will not only prevent breakdowns and production loss, but ensure a positive experience during state inspections, as you will need to show certification of inspection on each boiler. (Each state varies in the regularity of inspections, so check with your state legislature for current laws. We’ll discuss current Kentucky State law below.)

III. INSURANCE: Because of the potential risks involved to employees and property within range of the commercial boiler systems, insurance also requires compliance of current codes laid out by National and State Compliance laws, as well as additional checks that may be stated in your policy. Check with your current business insurance provider to ensure you are meeting their standards and requirements for continued insurance coverage.

IV. ENERGY EFFICIENCY: With regular maintenance, a checklist of each boiler system parts are analyzed to ensure the highest efficiency of your system, including but not limited to: cracks and integrity of the tubes and tube sheets, lime deposits or buildup, faulty electrical connections to prevent overheating, gaps in the spark rods, hairline fractures in the ceramic retainer, and irregular flue gas operations. All of which can decrease efficiency, utilizing more fuel, water or electricity to maintain needed heat or pressure, as well as cause additional problems down the line. When you regularly ‘tune’ your boiler, you ensure the burner and combustion are modulating correctly, thus preventing waste of gasses going up the flue. The annual preventative maintenance checks may even discover ways to increase efficiencies.

V. PREVENTION: Prevent production downtime, loss of heat and comfort for your staff, and costly repairs or replacement, not to mention the cost and danger involved in a boiler room disturbance (or explosion). Granted there is a small cost involved to ensure regular maintenance of your commercial boiler, but it is worth the peace of mind and continued safety of your commercial facility. Ensuring a properly functioning boiler also provides benefits by increasing the life of the boiler, maximizing efficiency and energy use, and reduced chance of carbon Monoxide Poisoning.

Kentucky State Laws for Commercial Boiler Inspections

In the Commonwealth of Kentucky, commercial High pressure steam boilers needed to be checked by a licensed boiler contractor once a year, and low pressure steam and hot water boilers at least every other year (24 months), according to Kentucky State Law. According to Kentucky Legislature, KRS Chapter 236:

“Each boiler or pressure vessel used or proposed to be used within this state, except boilers or pressure vessels exempt under KRS 236.060, shall be thoroughly inspected as to their construction, installation, and condition as follows: Power boilers shall receive a certificate of inspection annually which shall be an internal inspection where construction permits; otherwise it shall be as complete an inspection as possible. Low pressure steam or vapor heating boilers, hot water heating boilers, and hot water supply boilers shall receive a certificate of inspection biennially; said inspection shall include internal inspection where construction permits. External inspections shall be required where construction does not permit internal inspection.” (See Chapter 236.110 )

Licensed & Qualified to Maintain Commercial Boilers

The classification of Commercial Boilers is specific to any boiler system or water heater that is over 199,000 BTUs. input *And only a Licensed Commercial Boiler contractor is legally certified to maintain, repair or inspect systems that are over 199,000 BTUs.

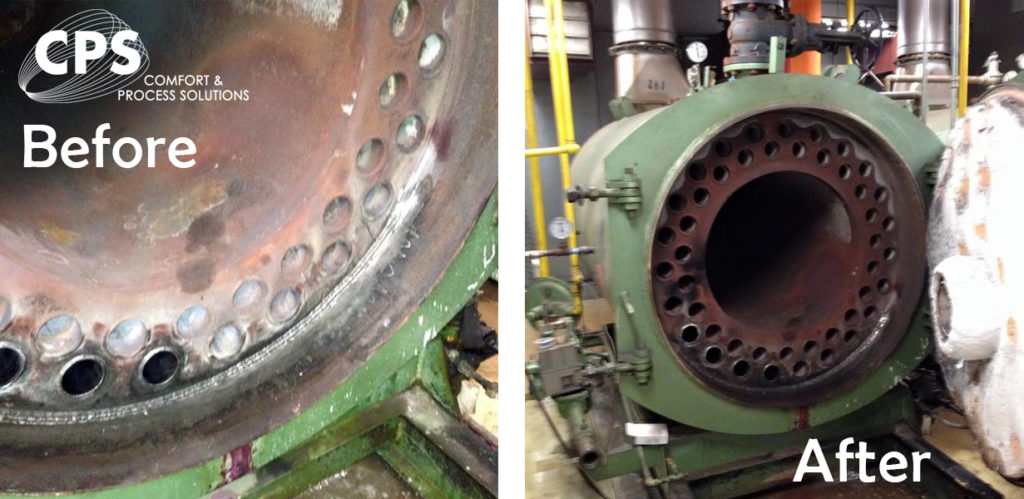

It’s currently required to be R Stamp certified to make any repairs to the tube sheet or pressure vessels, as welding is required to repair or replace the metal. If a tube sheet is cracked, the licensed Commercial Boiler contractor will weld the area to fill in the cracks on the pressure vessel. Smaller cracks or hairline fractures can be determined by using a dye penetrant kit an instrument emitting a black light. In Kentucky, the laws required that only an R Stamp Certified inspector is certified to weld on a Commercial Boiler pressure vessel.

“The National Board offers the Certificate of Authorization and R symbol stamp for the repair and/or alteration of boilers, pressure vessels, and other pressure-retaining items.” (More info: The National Board of Boiler and Pressure Vessel Inspectors)

Commercial Boiler Preventative Maintenance Checklist

Comfort and Process Solutions, not only has a Licensed, Certified Commercial Boiler inspector on staff, but we have over thirty years’ experience in the inspection, maintenance and installation of commercial boilers. We inspect, maintain and repair all types and brands of Commercial Boilers. We take the Preventative Maintenance process seriously, which begins with detailed record keeping and meticulous examination of all parts and processes of your system. For larger Scotch-marine boilers, Comfort & Process Solutions provides complete boiler open & close, including complete boiler re-tubes & vessel work including tube sheet dye penetrate tests and tube sheet repairs that require welding (R-stamp).

The process of inspection begins with the careful opening and closing the boiler system in a safe and controlled way, so we can inspect the tubes and tube sheets for cracks or lack of integrity, inspect the fouling of water treatment, lime deposits on the tubes which decrease efficiency, and brush out any deposits with our special equipment that cleans out the tubes efficiently. Opening and closing of the boiler system is imperative to the safety and increased lifespan of the equipment, hence why we include it on all our annual or semi-annual maintenance appointments. If hairline cracks, that cannot be detected otherwise, are not repaired they can pose a detrimental safety risk including a boiler room disturbance.

Depending on the type of boiler and brand there are different types of audits, maintenance and tuning of certain items that should be done. It is best to follow each manufacturer’s specific recommendations. Some of the more common checks include:

check and tests low and high gas pressure safeties;

check and tests low and high gas pressure safeties;- inspect and clean all burners of any modulating-condensing boilers;

- inspect all manhole gaskets for leaks;

- inspect all refractory systems;

- inspect and test all safety valves;

- clean and rebuild low water cut-off;

- recalibrate all operating controls;

- inspect and tighten electrical terminals,

- check low water cutoffs;

- inspect all flue chimneys and examine the flue gasses;

- tune boiler for optimal boiler efficiency;

- inspection of vent pipe for white, powdery residue;

- examination of all flame-sensing rods, spark rods to ensure they are properly gapped;

- check all fans and blowers for building of dirt;

- check of all electrical connections;

- check of block valves and bleed valves for any leaks;

- monitor oxygen, carbon monoxide and carbon dioxide levels.

This is not a complete list but well illustrates the need for regular examination of your commercial boilers to increase safety and the lifespan of your system, as well as prevent any costs of extreme repairs or production downtime.

Comfort & Process Solutions is a commercial and industrial HVAC company, serving all 120 counties of Kentucky. We specialize in chillers, boilers, plumbing, VRF systems, building automation, and industrial piping. We offer 24/7 Emergency Service for all your commercial HVAC needs. Call us to schedule your Commercial Boiler Preventative Maintenance today: (859) 294-4400 or visit: https://cpslex.com/contact-cps-lexington-ky/

2 Comments