It seems a bit too early to be talking about Spring or even Summer weather when the temperatures are still hovering in the 30-40’s this week and talk of possible flurries in the forecast, but here in the Bluegrass, everyone knows how quickly the weather can change.

“Welcome to Kentucky, the only state where you’ll wear shorts one day and a snow suit the next.”

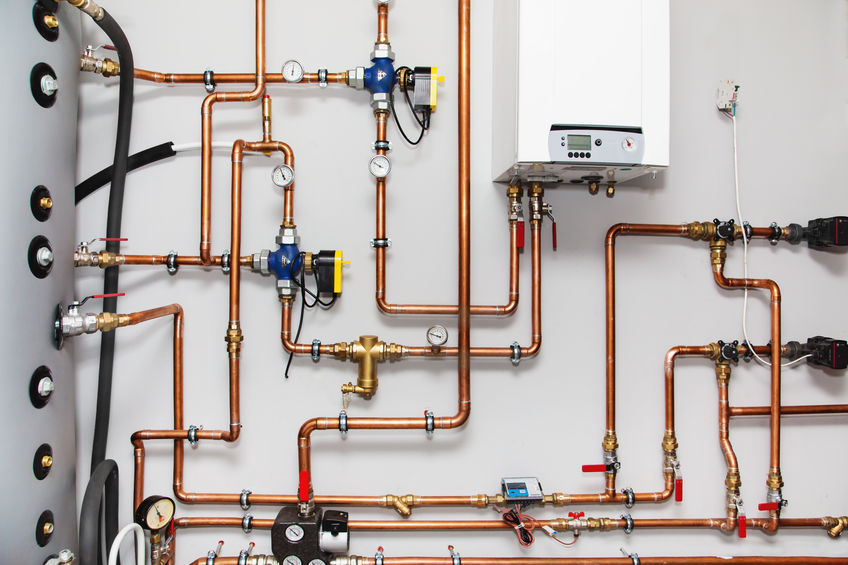

While it doesn’t seem possible now, within just a few weeks’ time, our commercial clients will need to turn on and utilize their cooling systems, after months of inactivity. To ensure functionality and efficiency when needed, our Cooling Preventative Maintenance includes a tune-up, testing and troubleshooting of the following:

Tune up of the Cooling Towers

Tune up of the Cooling Towers- Rodding out the Chiller Barrel

- Cleaning, greasing and replacing belts

- Inspect and clean steam traps

- Inspect backflow preventer

- Inspect coils on rooftop equipment for grime, buildup or cracks

- Inspect drift eliminators for proper positioning and scale build

- Physically clean the screen of all debris.

- Check for excessive vibration in motors, fans, and pumps.

- Check for loose fill, connections, leaks, rust, corrosion, etc.

- Check all belts, pulleys, nozzles and bearings – clean and adjust as needed.

- For an open cooling tower, test the water for proper concentrations of dissolved solids and chemistry.

- Inspect fan blades for any cracks, erosion or buildup of debris.

- Check gears, strains and bottom for corrosion, rust or buildup.

- Inspect and address any issues with the electrical system, including contacts, and motors

- Check levels of refrigerant and supplement if needed.

Why should you schedule your Spring PM now?

First of all, the system is currently not in use with the colder temperatures, so this is the perfect time to fully inspect, clean, and replace any parts while the system is already shut down. If you wait when the temperatures and humidity start to climb, your system will have to be shut down and out of use when you, your staff and your production lines need the cooling system. This could result in downtime of production, as well as temporary discomfort for your staff, customers, student body and patients (in the healthcare industry).

First of all, the system is currently not in use with the colder temperatures, so this is the perfect time to fully inspect, clean, and replace any parts while the system is already shut down. If you wait when the temperatures and humidity start to climb, your system will have to be shut down and out of use when you, your staff and your production lines need the cooling system. This could result in downtime of production, as well as temporary discomfort for your staff, customers, student body and patients (in the healthcare industry).

Second, if there are parts or even entire systems that need to be ordered, replaced and installed, this gives our staff the needed time to await the shipping of your items, which could take several days to several weeks, depending on the specialty of the item and the size of the equipment that is needed. This gives our staff sufficient time to make the needed repairs and replacement well before the equipment will be needed to cool the air.

Another reason to have regular scheduled PMs through the year or at least annually, is it ensures your equipment is running at the highest efficiency which provides a significant savings in energy costs. When the parts and equipment are clean, the system is going to run cleaner, safer, more efficiently and use less energy. If there is a buildup of grime or debris anywhere in the cooling system, the process of cooling is going to take longer and use a great deal more energy.

CASE STUDY: One of our local industrial clients came to us after years of requiring their boiler system needing to be rebuilt at least once a year, costing the company thousands of dollars and loss of production time during shutdown. After several years of this excessive cost with other HVAC companies, they called Comfort & Process Solutions. Instead of rebuilding the system again, our staff began to investigate why this was happening, and what was causing the chiller to fail each year. Our staff realized that a repair would be futile if we first did not determine the cause and prevent another costly rebuild. The company’s manager had replied, “No one has ever asked us why this happening before.” That is the CPS difference … we have the knowledge, training, certifications and over 30 years of field experience in commercial and industrial HVAC to not only repair but prevent further breakdowns.

Sign up for the Comfort & Process Solution’s Preventative Maintenance Program

If you have signed up for the Comfort & Process Solution’s PM annual contract, then our staff will automatically call you to schedule your next PM. Business owners and their staff are already inundated with daily tasks and maintenance of running their business, they will often forget or neglect their cooling systems especially when not in use or when everything seems to be running fine. The advantage of our PM contract, is that our clients will be sent either a postcard or receive a phone call to schedule an appointment at their convenience. No need to worry or stress, we will keep our records up to date so we know when your next PM should be scheduled.

PM for Schools, Colleges & Universities

Comfort & Process Solutions has been serving the heating and cooling needs of many of the local school districts in Kentucky, so we understand the specialized needs and state requirements of keeping their systems running efficiently, safely and the high priority of providing comfort to the faculty and students throughout the school year. That is why it’s imperative that schools, colleges and universities should be scheduling a full check and maintenance of their cooling system now, as the chillers and coolers are not currently in use. Avoid the shutdown later and call our staff today.

PM for Hospitals and Healthcare Facilities

For over 20 years, CPS has been providing industrial and commercial HVAC service to Kentucky, with an improved focus on customer service, an expanded team of certified, factory trained team and a renewed commitment to keep your business up and running 24 hours, 7 days a week. Our round-the-clock care is especially vital for our clients in the healthcare industry including hospitals, clinics, rehabilitation facilities, and senior care living centers. When it comes to patient care and comfort, CPS understands and prioritizes the heating and cooling needs of these organizations.

For over 20 years, CPS has been providing industrial and commercial HVAC service to Kentucky, with an improved focus on customer service, an expanded team of certified, factory trained team and a renewed commitment to keep your business up and running 24 hours, 7 days a week. Our round-the-clock care is especially vital for our clients in the healthcare industry including hospitals, clinics, rehabilitation facilities, and senior care living centers. When it comes to patient care and comfort, CPS understands and prioritizes the heating and cooling needs of these organizations.

When it comes to hospitals, the heating and cooling needs are year-round, regardless of the weather, as they need heat and hot water to sterilize, optimal temperatures for the comfort of the patients and staff, and air quality control is needed for precise air-exchange, humidity and temperature to minimize the risk of infection for patients.

For example, when inspecting and maintaining hospital cooling system, we conduct a steam trap survey to check compensation return, and efficient use of the feed water system. A steam trap is a device used to discharge condensates and non-condensable gases with a negligible consumption or loss of live steam. The steam traps use automatic valves that open, close and modulate the expenditure of steam, water cooling and reuse of the cooled, treated water. We also ensure that the backflow preventer is functioning to ensure that the pressure and back-syphoning is preventing water from being released into the ground water or plumbing system of the building.

An efficiently running system will ensure that 98% of the water is reused, rather than evaporated into the atmosphere or accidentally leaked into the drinking water. For the water to be reused, it has to be clean without need to be retreated before it reenters the system, otherwise the debris in the water would impair the process, and eventually cause system failure.

“Steam traps should be checked regularly, as they can make or break your system’s functionality and lifespan, and if maintained, it could save your business thousands of dollars.” – Jeff Fristoe

With over 20 years in business, we have a team of vetted technicians who are R-Stamp Certified, experienced, certified and factory trained. We are on call 24 hours a day, seven days a week to keep your business up and running, providing service and repair for:

Chillers & Boilers

Chillers & Boilers- Roof Top Units

- Make Up Air Units

- Cooling Towers

- De-humidification & Humidification

- Burners & Ovens

- Fans & Compressors

- Geothermal

- Server Room Conditioning

- Pumps, Piping and Plumbing

- VRF Systems

- Tube & Vessel Repair

- R-Stamp Certified

Call CPS today for an initial consultation with our management team to assess your need and development a PM program that works for your business.